HOT SALE

Variable Diameter FRP Core Tube

Product use: Winding and slitting of functional films such as copper foil, aluminum foil, optical films, etc

View DetailsFRP Rubber Core Tube (Corrosion resistance)

It can improve the steps and indentations caused by extrusion in early films.

View DetailsFiberglass Rubber Core (Product purpose:Electronic material thin film)

It can be used to make electronic material films and optical films.

View DetailsFRP Rubber Core Tube (Heat resistance)

It can improve the steps and indentations caused by extrusion in early films

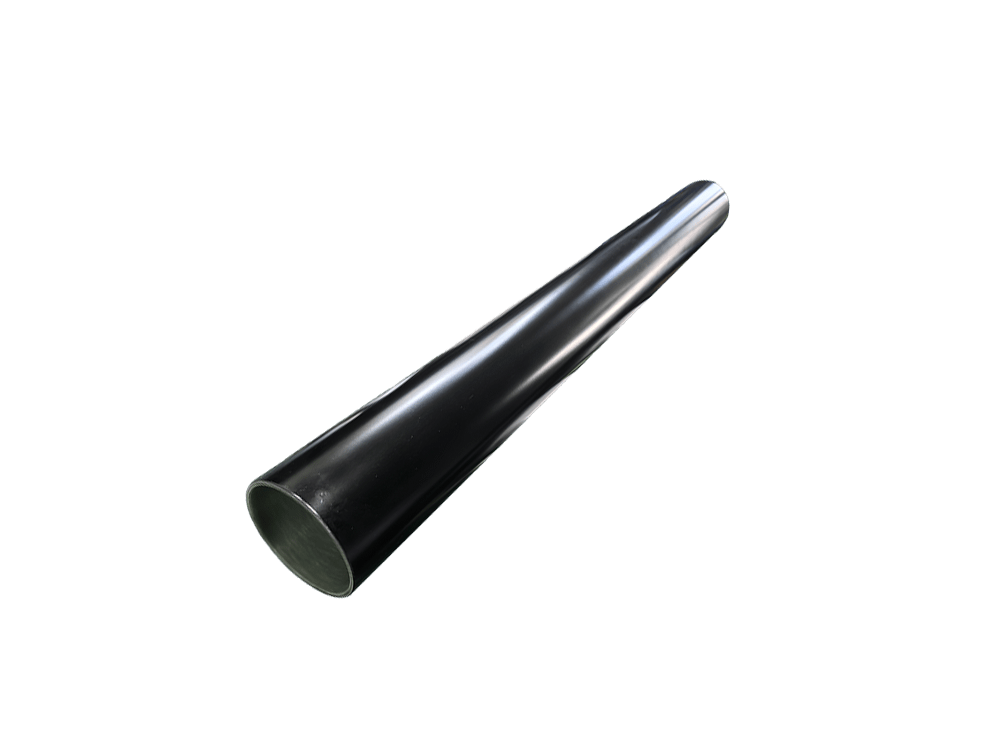

View DetailsFRP Coated Core (FRP Bare Tube for Industrial Use)

Filament winding process

Category:

Keyword:

mechanical

transformer

environments

FRP bare tube

Product details

FRP Bare Tube for Industrial Use plays an important role in the industrial field.

1. Material properties

FRP Bare Tube for Industrial Use is a composite of fiber and resin matrix. First of all, it has excellent corrosion resistance. In industrial environments, it is often faced with erosion by various chemical substances, such as acid and alkali solutions, corrosive gases, etc. FRP Bare Tube for Industrial Use can resist these corrosion factors, whether in highly corrosive industrial scenes such as chemical industry and electroplating, or in industrial facilities in high salt spray environments such as marine engineering, it can maintain good performance and greatly extend its service life.

Secondly, it is light in weight. Compared with traditional metal pipes, such as steel pipes, FRP Bare Tube for Industrial Use has a lower density, which has great advantages during installation. It reduces the load of the supporting structure, facilitates transportation and installation, and reduces the manpower and material costs in industrial construction.

2. Mechanical properties

FRP Bare Tube for Industrial Use has high strength. It can withstand certain internal pressures and external loads. In the process of industrial fluid transportation, a stable pipeline structure is essential. Whether it is used to transport liquid chemical raw materials or in some industrial circulating water systems with a certain pressure, FRP Bare Tube for Industrial Use can ensure safe and stable operation and is not prone to rupture or deformation.

In addition, it also has good fatigue resistance. In the case of long-term operation, frequent start-stop or periodic pressure changes of industrial equipment, FRP Bare Tube for Industrial Use can still maintain structural integrity and reduce the frequency of maintenance and replacement.

3. Temperature adaptability and other advantages

FRP Bare Tube for Industrial Use can adapt to a certain range of temperature changes. Temperature fluctuations are common in different industrial processes, and it can work normally in a wider temperature range. Moreover, FRP Bare Tube for Industrial Use is also a non-conductive material, which is very suitable for some industrial environments that require electrical insulation, such as special fluid delivery pipelines in electronic industrial plants, which effectively avoids safety hazards that may be caused by pipeline conductivity.

previous page

previous page

Related Products

Fiberglass Rubber Core (Product purpose:Electronic material thin film)

It can be used to make electronic material films and optical films.

FRP Rubber Core Tube (Heat resistance)

It can improve the steps and indentations caused by extrusion in early films

FRP Rubber Core Tube (Corrosion resistance)

It can improve the steps and indentations caused by extrusion in early films.

FRP Rubber Core (Repackable design)

It can improve the steps and indentations caused by extrusion in early films

High temperature resistant core tube

FRP Coated Tube for Power Transmission is an advanced pipe product designed for high temperature environments.